Polymer Composite Diamond Coatings

Series 1000 Polymer Coatings

For Most Ferrous & Non-Ferrous Metals

Polymer composite diamond coatings combine the benefits of a composite diamond coating (a unique, patented technology for dispersing diamond particulate throughout an autocatalytic nickel alloy) with a proprietary infused fluoropolymer matrix. This technology allows Endura®Coatings to apply and integrate diamond with specialized polymers to most alloy surfaces. The combination offers unparalleled benefits of wear resistance, surface hardness, high release, non-stick, low friction, and dry lubrication.

Coating Patents

Endura® has exclusivity within many of these patents. CDC is covered by these U.S. Patents:

- 4,997,686

- 5,145,517

- 5,300,330

- 5,863,616

- 6,306,466

Series 1000 - Polymer Coating Process

For Most Ferrous & Non-Ferrous Metals

Processing Illustrations

At Endura Coatings, we offer the Series 1000 Polymer Infused Composite Diamond Coating for dispersing diamond particulates throughout an autocatalytic nickel alloy matrix. Our proprietary infusion process alloys us to apply and integrate diamond to most alloy surfaces for a wide range of applications used in a variety of industries.

Step 1: Our proprietary surface cleaning.

Step 2: Our bath deposition process.

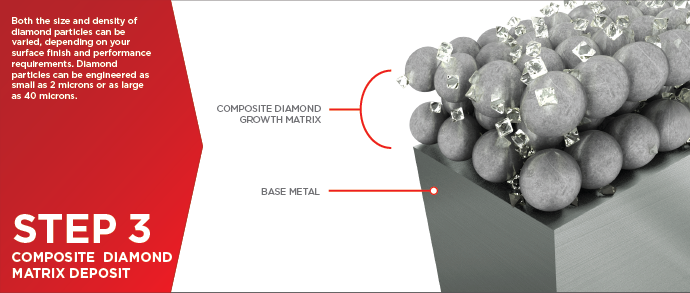

Step 3: Composite Diamond Matrix Deposit. Both the size and density of diamond particles can be varied, depending on your surface finish and performance requirements. Diamond particles can be engineered as small as 2 microns or as large as 40 microns.

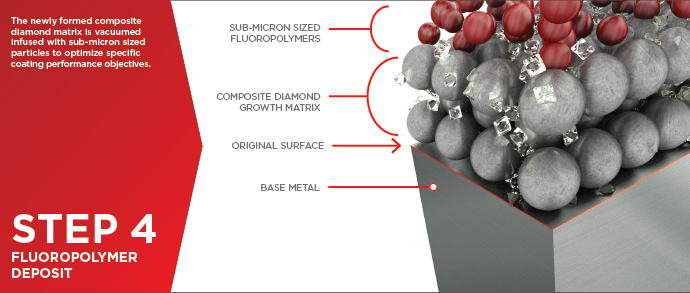

Step 4: Fluropolymer Deposit. The newly formed composite diamond matrix is vacuumed infused with sub-micron sized particles to optimize specific coating performance objectives.

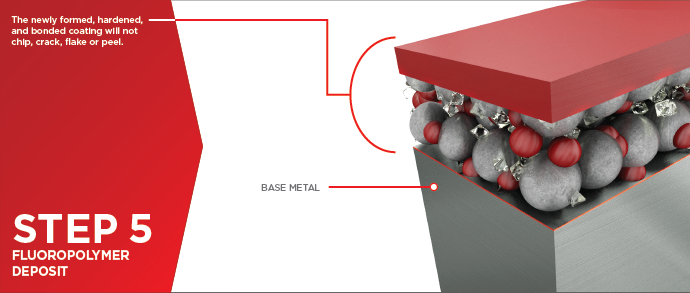

Step 5: Fluropolymer Deposit. The newly formed, hardened, and bonded coating will not chip, crack, flake or peel.

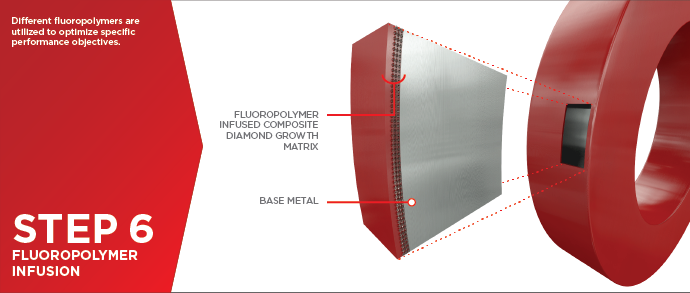

Step 6: Fluropolymer Infusion. Different fluoropolymers are utilized to optimize specific performance objectives.

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings