Dry & Solid Film Lubricant Coatings

Series 400 Solid / Dry Film Lubricant Coatings

For Ferrous & Non-Ferrous Metals

Solid / dry film lubricants are unique finishes engineered to provide exceptional dry lubrication, and often serve as a more robust product alternative to traditional lubricants and anti-seizing agents such as superficial oils. Depending on your application requirements or desired military or industry specification, dry / solid film lubricants provide benefits by protecting tooling from galling, seizing, fretting and corrosion.

Dry film lubricants can be utilized in applications with extreme temperature ranges (from sub-zero to 1200° F) and resist out-gassing under vacuum for use in the aerospace and military industries. Endura® offers a range of these low friction coatings to satisfy your application requirements.

Our series 400 coating systems are compliant with a wide array of specifications developed by manufacturers and DEMIs in the aerospace, automotive, electronic, medical and plastic molding industries. For instance, we can certify to:

- MIL-L-46010C

- Type III

- MIL-PRF-46010 & MIL-PRF-46147D

- Type I

- Form 1 & 2

If you have a dry film coating specification you would like us to review, click on the below link to complete our Coating Requirement Questionnaire and be sure to include prints or drawings with your submission.

Series 400 - Solid Film & Dry Film Lubricant Coating Process

For Ferrous & Non-Ferrous Metals

Processing Illustrations

At Endura Coatings, we offer solid / dry film lubricant coatings as part of our Series 400 coating solutions. Dry film lubricants can be utilized in applications with extreme temperature ranges (from sub-zero to 1200° F) and resist out-gassing under vacuum for use in the aerospace and military industries. As part of our process, we have 5 steps for these coatings.

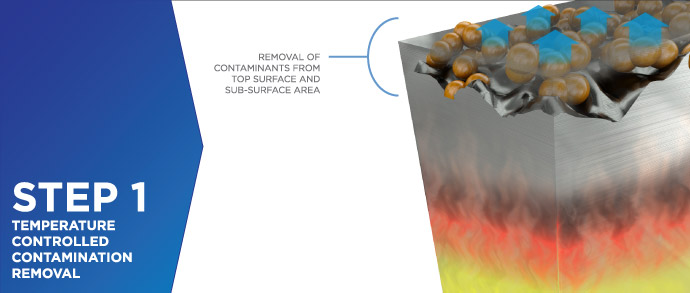

Step 1: Temperature controlled removal of contimants on top surface area and sub-surface area.

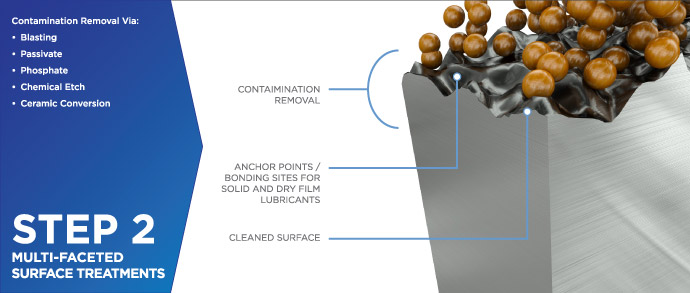

Step 2: Multi-Faceted Surface Treatments. The contimination removal happens via blastings, passivate, phosphate, chemical etch and ceramic conversion. Anchor points or bonding sites are created for solid and dry film lubricants. And the substrate now has a clean surface

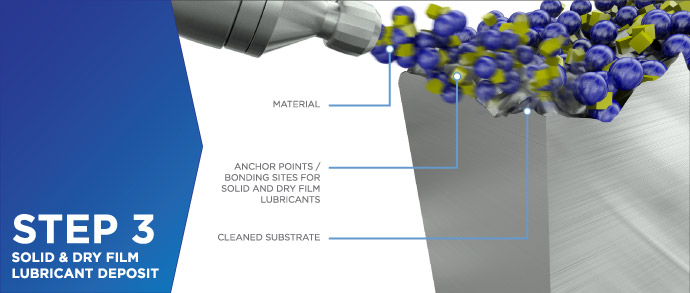

Step 3: Solid and Dry Film Lubricant Deposit.

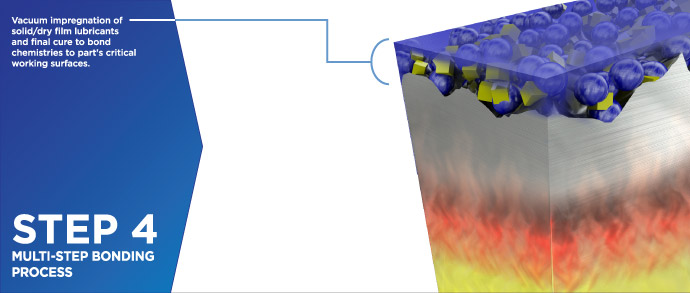

Step 4: Multi-Step Bonding Process. Vacuum impregnation of solid and dry film lubricants and final cure to bond chemistries to part's critical working surfaces.

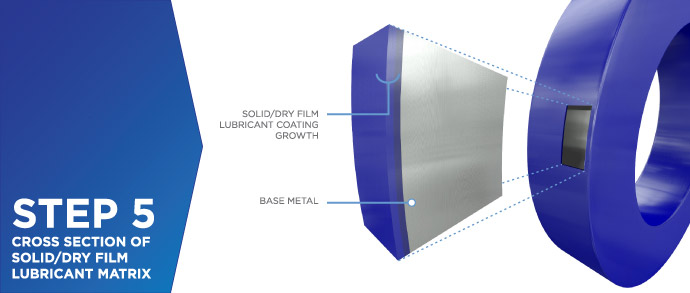

Step 5: Cross section of solid / dry film lubricant matrix.

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings