Hard Chromium Plating

Series 500 Hard Chromium Plating

For Ferrous Metals

By nature, chromium has a low coefficient of friction and is resistant to a wide variety of corrosive agents and materials. These attributes make hard chromium plating particularly attractive for applications plagued by accelerated wear and high friction. Compared to an uncoated surface, a chrome-plated work piece can provide increased in-service longevity, creating significant advantages to our customers by lessening or eliminating down-time and tool maintenance / replacement. Endura®'s functional hard chrome plating is used in a variety of industries and environments, such as applications in which durability and alloy protection is imperative.

By nature, chromium has a low coefficient of friction and is resistant to a wide variety of corrosive agents and materials. These attributes make hard chromium plating particularly attractive for applications plagued by accelerated wear and high friction. Compared to an uncoated surface, a chrome-plated work piece can provide increased in-service longevity, creating significant advantages to our customers by lessening or eliminating down-time and tool maintenance / replacement. Endura®'s functional hard chrome plating is used in a variety of industries and environments, such as applications in which durability and alloy protection is imperative.

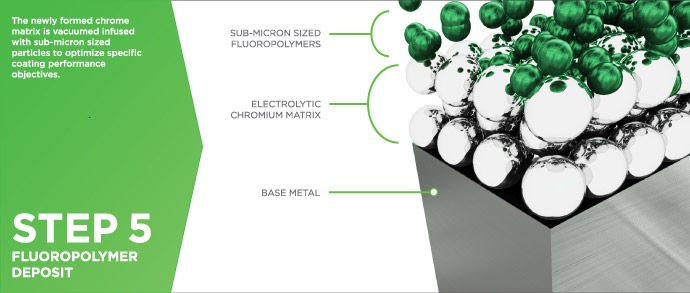

Need something more? Consider Endura®'s Infused Matrix™Coatings. These coating technologies are further reinforced with a variety of fluorochemistry enhancements which provide extra performance benefits including, but not limited to: superior corrosion resistance, low-friction and non-stick properties. Created by means of a proprietary vacuum impregnation process, our Infused Matrix coatings are truly unique, providing all of the benefits of traditional Teflon or "Teflon-like" coating within a wear-hardened ceramic matrix. These surface conversion technologies create improved release, lower friction, enhanced corrosion protection, and a harder, more wear-resistant surface than other chromium coatings available today.

Series 500 - Hard Chromium Plating Process

For Ferrous Metals

Processing Illustrations

At Endura Coatings, we offer our Series 500 Hard Chromium Plating, using chromium's low coefficient of friction and high corrosion resistance for applications where durability and alloy protection is important. As part of our hard chromium plating process, we have seven steps.

Step 1: Our proprietary surface cleaning

Step 2: Parts go through an acid etch pretreatment to prep the metal substrate for plating. Different acid etching solutions are used for different substrates.

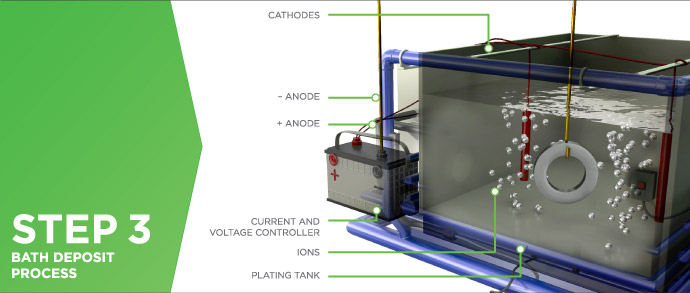

Step 3: Bath deposit process occurs in step 3

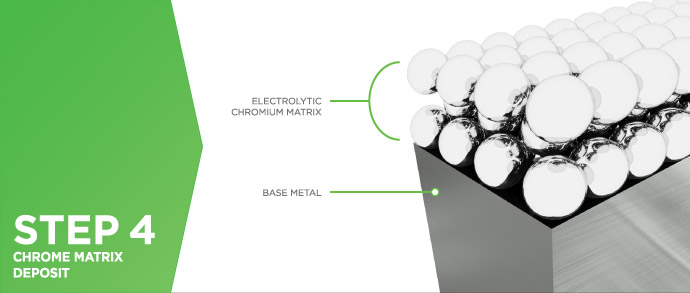

Step 4: Chrome matrix deposit is formed

Step 5: The newly formed chrome matrix is vacuumed infused with sub-micron sized particles to optimize specific coating performance objectives

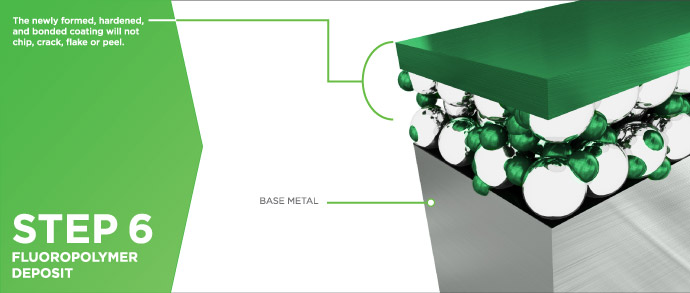

Step 6: The newly formed, hardened, and bonded coating will not chip, crack, flake or peel

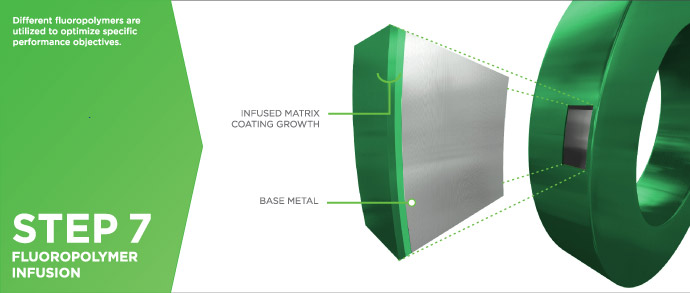

Step 7: Different fluoropolymers are utilized to optimize specific performance objectives

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings