Fluoropolymer Coatings

Series 300 Fluoropolymer Coatings

For Ferrous & Non-Ferrous Metals & Glass

A fluoropolymer is a polymer that contains molecules of carbon and fluorine. They are high-performance plastic materials used in harsh chemical and high-temperature environments, primarily where a critical performance spcification must be met. Fluoropolymer coating or "Teflon-like" coatings are engineered to create a wide array of performance benefits.

Fluoropolymer Features & Benefits

- Corrosion protection

- Dielectric Properties

- Lubrication

- Non-Stick

- Non-Wetting & Static Dissipation

- Squeak Suppression

Read more on our Fluoropolymer (Series 300) Performance Factors such as the hardenss equivalents from 55 to 80 Shore D.

Since 1970, our highly experienced teams of engineers and chemists at Endura have formulated an abundance of unique and proprietary technology solutions which offer a broad combination of performance advantages and surface characteristics above and beyond those of standard Teflon or "Telfon-like" finishes.

We regularly procure new material blends and invest in the latest material and application technologies for our fluoropolymer coatings. This commitment to continuous improvement ensures that we are on the forefront of innovation and meet or exceed our customers’ expectations of service and industry know-how.

FDA / USDA / NSF Approved Fluoropolymer Coating

Specific fluoropolymer coatings are FDA and NSF compliant, USDA approved, biocompatible per ISO 10993, and are used extensively in a variety of environments in which non-stick, insulating, and chemical or corrosive protective properties are paramount. We have a longstanding history of success in industries such as thermoforming, food and beverage processing and packaging, medical, pharmaceutical and diagnostics, and computer and business machinery components.

In addition to the many FDA / USDA / NSF approved coating systems we offer, Endura also provides services to the HVAC industry. We provide numerous custom engineered fluoropolymer coating systems specifically designed to withstand the aggressive service environments of industrial manufacturing plants, chlorinated pool facilities, coastal sea areas and medical facilities. Whether you are looking to mitigate corrosion to prolong the service life of your units, or increase their performance efficiencies; our proprietary, highly engineered coating systems can greatly increase the functional benefits of HVAC coils by reducing corrosion, friction, sticking, and wear.

If you are looking for assistance in fabrication, please contact Coil Replacement Company to provide custom and direct OEM heating and cooling solutions.

Along with our proprietary resin formulations, we offer and apply most of the major fluoropolymer families:

| Fluoropolymer Type | Fluoropolymer Description |

|---|---|

| ECTFE Ethylene chlorotrifluoroethylene |

Designed to provide unrivaled chemical corrosion protection, ECTFE possesses the best permeation resistance of all of the fluoropolymer families. This coating can resist most oxidizing agents, solvents, caustic media and even high concentration of strong acids at elevated temperatures. Similar to ETFE, ECTFE is a good electrical insulator providing excellent dielectric properties and a low dissipation factor. |

| ETFE Ethylene tetrafluoroethylene |

Predominately a fluorine-based polymer system, this coating system possesses outstanding chemical resistance, dielectric insulation and radiation resistant performance properties. |

| FEP Fluorinated ethylene propylene |

Similar in both physical composition and performance to PTFE and PFA, FEP is a softer copolymer system that possesses exceptional non-stick characteristics and a lower melt point (500F) compared to that of PFA and PTFE. |

| PTFE Polytetrafluoroethylene |

Most commonly referred to as “Teflon”, PTFE is a high-molecular weight fluorocarbon that is hydrophobic in nature. This polymer is primarily used to provide exceptional low friction and wear resistant surface properties in combination. It possesses one of the lowest coefficients of friction of any solid. It is the most commonly used fluoropolymer, found on everything from cooking pans to catheters. |

| PVDF Polyvinylidene Fluoride |

Produced by the polymerization of vinylidene difluoride, PVDF is a pure thermoplastic fluoropolymer. It’s highly non-reactive properties make it ideal for chemical use environments, as it will resist attack from most solvents, acids and bases. |

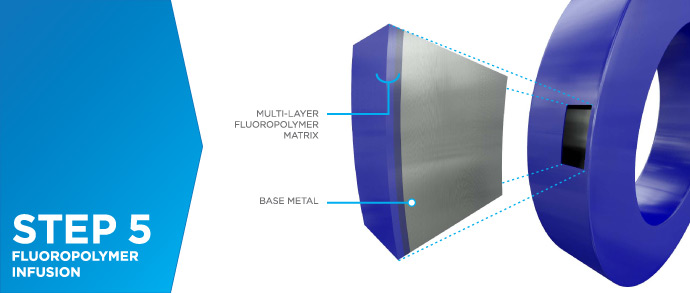

Series 300 - Fluoropolymer Coating Process

For Ferrous & Non-Ferrous Metals, & Glass

Processing Illustrations

At Endura Coatings, we offer our Series 300 Fluoropolymer coatings that are engineered to provide lubrication, corrosion resistant and low friction surface properties. This can be applied to the majority of metal substrates including; steel, stainless steel, iron, brass, bronze, copper, hastelloy, inconel, monel, nickel alloys and aluminum

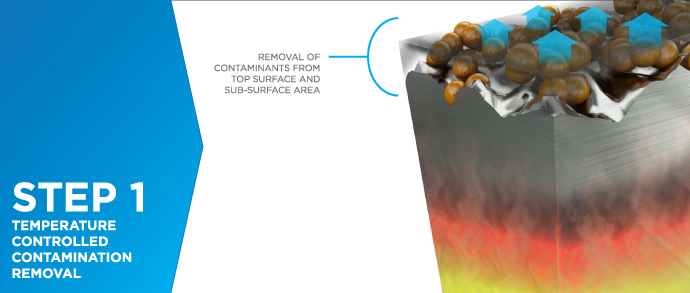

Step 1: Temperature controlled contaimination removal from top surface and sub-surface area

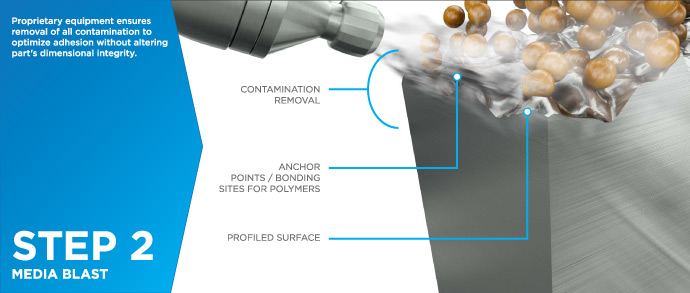

Step 2: Proprietary equipment ensures removal of all contamination to optimize adhesion without altering part's dimensional integrity

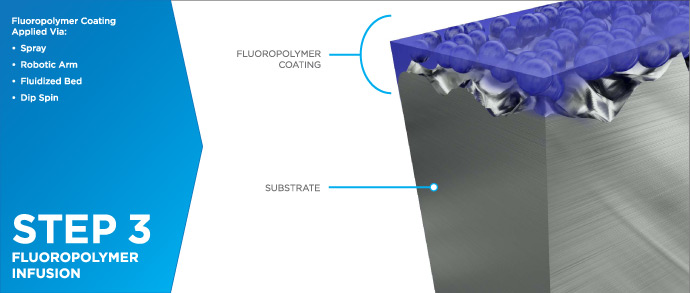

Step 3: Fluoropolymer coating applied via spray, robotic arm, fluidized bed and dip spin methods.

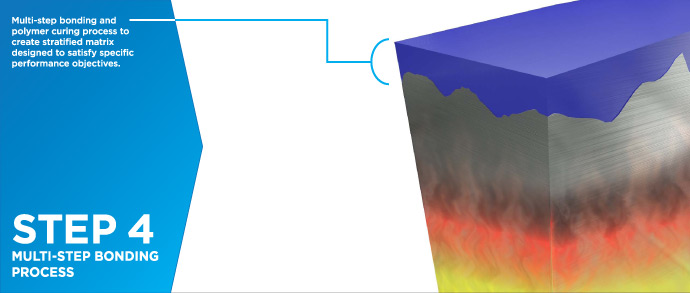

Step 4: Multi-step bonding and polymer curling process to create stratified matrix designed to satisfy specific performance objectives

Step 5: Fluoropolymer infusion occurs as the final step

Read more on our Fluoropolymer Coating specifications and performance factors.

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings