Ceramic Composite Coatings

Series 100 Ceramic Composite Coatings

For Aluminum & Magnesium Substrates

Endura®'s Ceramic Hard Coatings are created with a proprietary immersion-based spark deposition process, which transforms the outermost layer of your aluminum or magnesium substrate into a ceramic oxide. Under an applied electric waveform, the parent metal (your work piece) combines with elements in an acid-based electrolyte to form a protective layer of ceramic. These coatings encapsulate your tooling to create a highly uniform coating, which replicates all surface geometry and provides excellent resistance to wear and corrosion.

Endura®'s Ceramic Hard Coatings are created with a proprietary immersion-based spark deposition process, which transforms the outermost layer of your aluminum or magnesium substrate into a ceramic oxide. Under an applied electric waveform, the parent metal (your work piece) combines with elements in an acid-based electrolyte to form a protective layer of ceramic. These coatings encapsulate your tooling to create a highly uniform coating, which replicates all surface geometry and provides excellent resistance to wear and corrosion.

View the performance factors for each Series 100 Ceramic Coating >>

Need something more?

Consider Endura®'s Infused Matrix™ coatings. These coating technologies are further reinforced with a variety of fluorochemistry enhancements which provide extra performance benefits including, but not limited to: superior corrosion resistance, low-friction and non-stick properties. Created by means of a proprietary vacuum impregnation process, our Infused Matrix™ coatings are truly unique, providing all of the benefits of traditional Teflon or “Teflon-like” coating within a wear-hardened ceramic matrix. These surface conversion technologies are used throughout several industries because they create improved release, lower friction, enhanced corrosion protection, and a harder, more wear-resistant surface than other anodic coatings available today.

Series 100 - Ceramic Composite Coating Process

For Aluminum & Magnesium

Processing Illustration

At Endura Coatings, we offer composite ceramic coatings which go through the following process:

Step 1: Endura's proprietary surface cleaning.

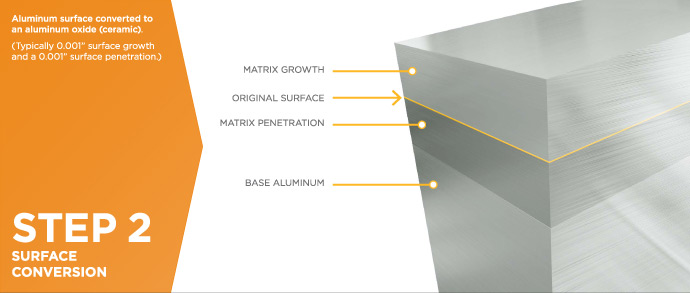

Step 2: The aluminum surface is converted to aluminum oxide (ceramic).

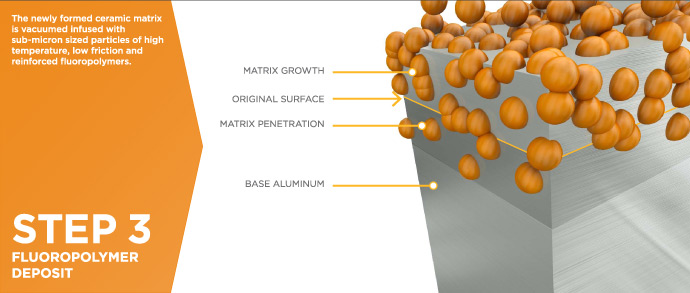

Step 3: The newly formed ceramic matrix is vacuum infused with sub-micron sized particles of high temperature, low friction and reinforced polymers.

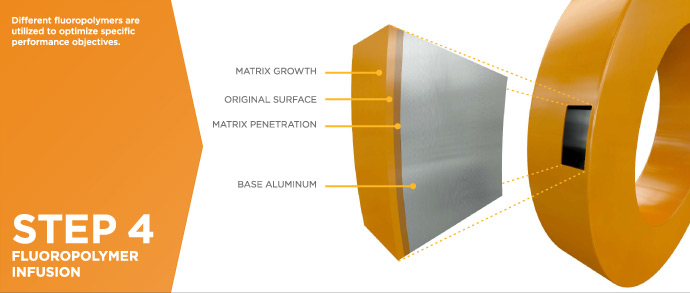

Step 4: Different flouropolymers are utilized to optimize specific performance objectives.

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings