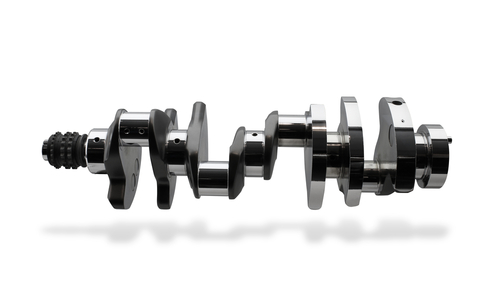

Electroless Nickel Plating Coatings

Series 200 Electroless Nickel Plating

For Ferrous & Non-Ferrous Metals

Electroless nickel coatings are an immersion-based nickel alloy technology which conforms to most complex geometries of ferrous and non-ferrous surfaces. Traditionally, electroless nickel plating technologies provide a multitude of benefits including added hardness, wear and corrosion protection. Depending on your specific performance needs, chemistries can be modified to enhance those properties. These variations may also provide unique dry film lubrication and can be used at temperatures in excess of 1000° F.

We offer a vast array of RoHS compliant electroless nickel plating systems of which include, but are not limited to:

- Composite Diamond Coatings

- Electroless Nickel with Boron Nitride

- Electroless Nickel Teflon (EN & PTFE)

- High Phosphorous Electroless Nickel (x>10%)

- Medium Phosphorous Electroless Nickel (6-9%)

In addition to the above plating systems, we are also able to meet a multiplicity of plating specifications. These specifications are seen in applications throughout various industries such as aerospace and military. The two most common plating specifications we can certify are MIL-C-26074 and ASTM B733, of which can meet:

MIL-C-26074

Classes:

- Class 1

- Class 2

- Class 3

- Class 4

Grades:

- Grade A

- Grade B

- Grade C

ASTM B733

Types:

- Type I

- Type IV

- Type V

Classes:

- Class 1

- Class 2

- Class 3

- Class 4

- Class 5

SC(Service Condition)

- SC 1

- SC 2

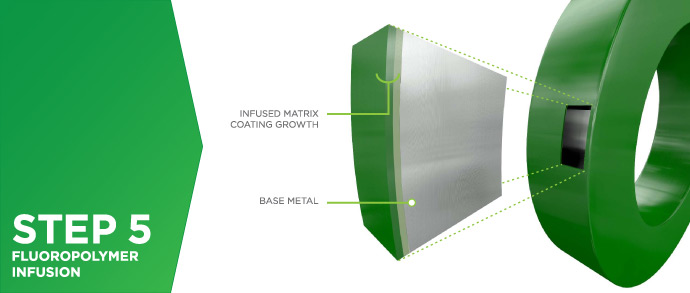

- SC 3

Need something more? Consider Endura®'s Infused Matrix™ coatings. These coating technologies are further reinforced with a variety of fluorochemistry enhancements which provide extra performance benefits including, but not limited to: superior corrosion resistance, low-friction and non-stick properties. Created by means of a proprietary vacuum impregnation process, our Infused Matrix™ coatings are truly unique, providing all of the benefits of traditional Teflon or “Teflon-like” coating within a wear-hardened nickel matrix. These surface conversion technologies create improved release, lower friction, enhanced corrosion protection, and a harder, more wear-resistant surface than other nickel-based coatings available today.

Specific nickel plating-based coatings are RoHS and FDA compliant, USDA approved and biocompatible (ISO 10993).

Series 200 - Electroless Nickel Plating Process

For Ferrous & Non-Ferrous Metals

Process Illustration

At Endura Coatings, we offer our Series 200 Electroless Nickel Plating, used to deposit a coating of nickel on a substrate for increased wear and corrosion protection. As part of our electroless nickel plating process, we have five steps.

Step 1: Our proprietary surface cleaning

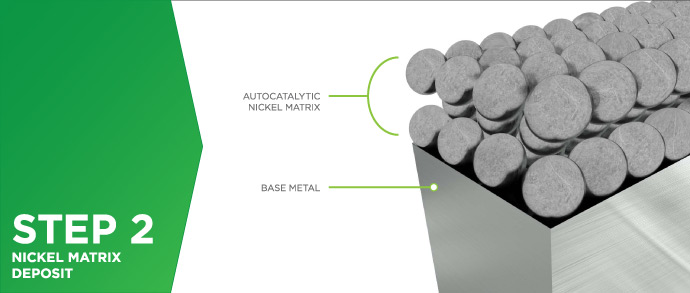

Step 2: Where the auto-catalytic nickel matrix reaction happens

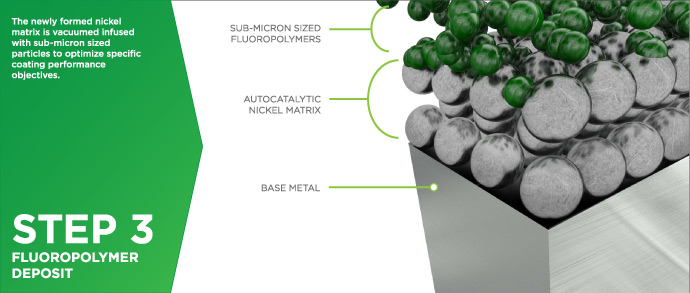

Step 3: The newly formed nickel matrix is vacuumed infused with sub-micron sized particles (fluoropolymers) to optimize specific coating performance objectives

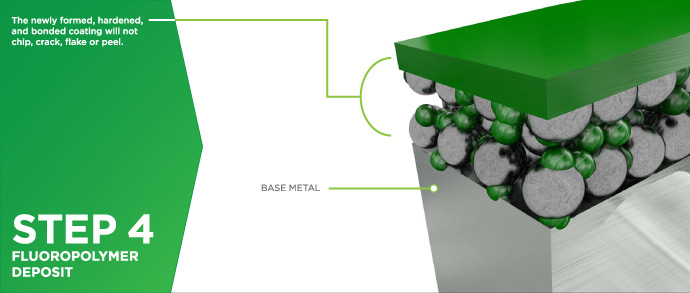

Step 4: The newly formed, hardened and bonded coating will not chip, crack, flake or peel

Step 5: Fluoropolymer infusion with our infused matrix coating

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings