Liquid Ceramic Insulation Coatings

Series 700 Liquid Ceramic Coatings

For Ferrous & Non-Ferrous Metals

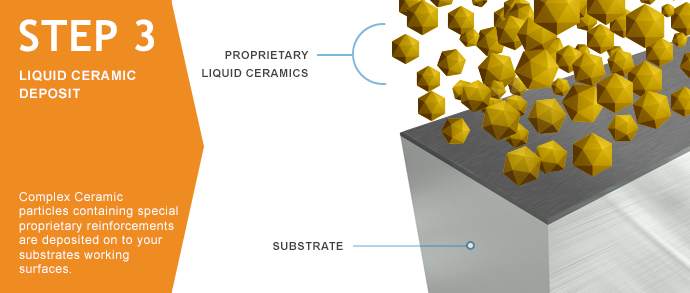

Endura®'s Liquid Ceramic Coatings represent our latest advancements in ceramic insulation coating technology. Complex ceramic particles combine with proprietary resins and copolymer reinforcements to create surface architectures that are highly robust. Applied via a proprietary application process, our 700 Series coatings are highly conformal and can afford:

- High dielectric strength (over 6,000 volts of insulation have been achieved with only 140 microns of coating thickness applied).

- High heat stability (up to 1,500°F)

- Improved surface hardness

- Resistance to salt spray corrosion (up to 1,000 hrs per ASTM B117)

- Scratch resistance

- Thin film deposits

Available in a wide array of colors, our Endura 700 Series cermaic insulation coatings have enjoyed considerable success across a wide range of industries and use applications, spanning everything from various commercial products, functional automotive components and military firearms.

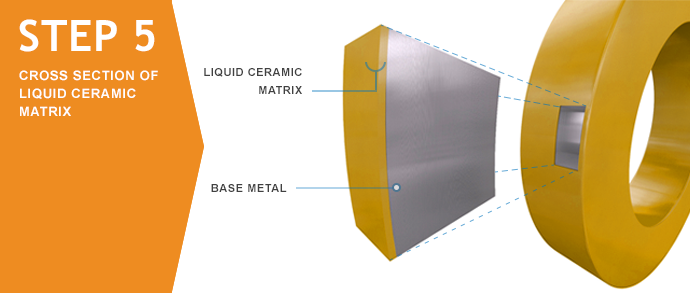

Series 700 - Liquid Ceramic Coating Process

For Ferrous & Non-Ferrous Metals

Processing Illustration

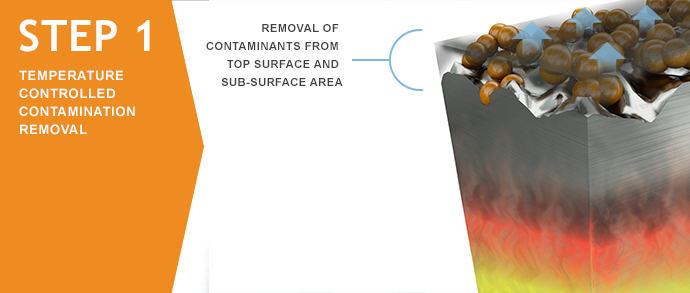

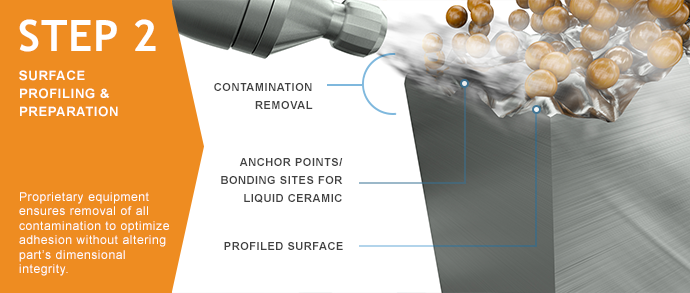

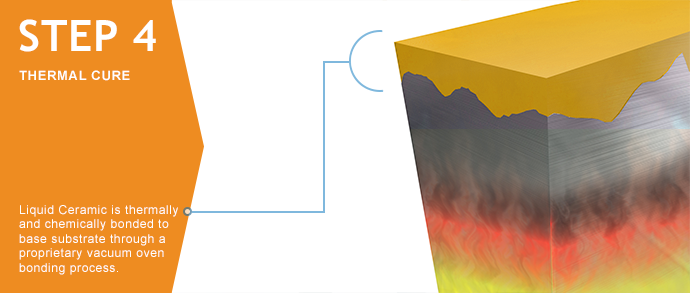

Our liquid ceramic coatings go through the following processes:

Step 1: Removal of contaminants from top surface and sub-surface area.

Step 2: Proprietary equipment ensures removal of all contamination to optimize adhesion without altering part's dimensional integrity.

Step 3: Ceramic particles, containing special proprietary reinforcements are deposited on to your substrates working surfaces.

Step 4: Liquid ceramic is thermally and chemically bonded to the base substrate through a proprietary vacuum oven bonding process.

Step 5: Liquid ceramic coating is complete.

Please complete our Coating Requirement Questionnaire

or call us

at 1.800.336.3872 to review & discuss your project requirements.

Endura Coatings

Endura Coatings